| View previous topic::View next topic |

| Author |

Message |

B.V.Harsoda

General Sponsor

Joined: 19 Jan 2009

Posts: 2329

Location: RAJKOT,GUJARAT, INDIA

|

Posted: Sun Oct 05, 2014 4:11 pmPost subject: Need of Detailing Awareness For Safe Structures Posted: Sun Oct 05, 2014 4:11 pmPost subject: Need of Detailing Awareness For Safe Structures |

|

|

Dear All,

I want to raise the Topic"Need of Detailing Awareness For Safe Structures", as I feel, it is very very important. Computer software is commonly used to provide design information, but without proper detailing & site awareness regarding detailing, design Strength can not be achieved.

Below given case I have read from Book:-

Failures in Concrete structures

By

Robin Whittle

Case of Failure of two way slab due to lack of awareness of Site Engineer toward Detailing:-

"A two-way spanning slab was designed in accordance with the design rules.One side was significantly longer than the other and this meant that the reinforcement provided for the short span was considerably greater than that for the long span.When the drawing arrived on site, the site engineer decided that the drawing contained a mistake and that the reinforcement in the long span should be the greater. He instructed the reinforcement layout to be swapped around and the slab was built that way. Later, when the full load was applied, the slab collapsed."

All of us has Design Footings, but how many has deeply observed reinforcement placing at site is the question ?

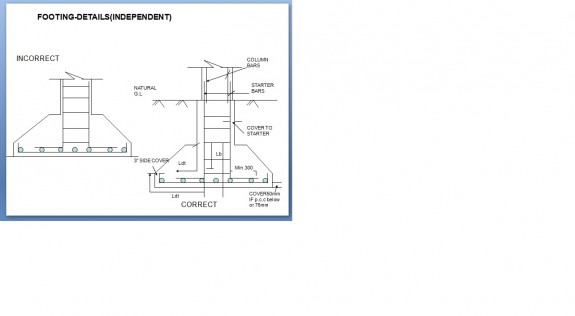

Please Refer below two Figures & say which method of reinforcement arrangement is correct and why ?

Warm Regards,

B. V. Harsoda

| Description: |

| Footing Size 2.75 m X 2.1m |

|

| Filesize: |

120.64 KB |

| Viewed: |

3662 Time(s) |

|

Last edited by B.V.Harsoda on Thu Jul 14, 2016 3:24 pm; edited 8 times in total |

|

| Back to top |

|

|

| Thankful People |

6user(s) is/are thankful for this post.mzcengr(30-10, 4:59),thirumalaichettiar(30-10, 9:35),er.ravichandran(10-11, 11:45),naveen(29-08, 4:13),anandjha(26-08, 6:33),PushkarKokane(23-02, 11:11), Thanks B.V.Harsoda for his/her post

|

|

thirumalaichettiar

Silver Sponsor

Joined: 26 Jan 2003

Posts: 3552

|

Posted: Sun Oct 05, 2014 4:33 pmPost subject: Posted: Sun Oct 05, 2014 4:33 pmPost subject: |

|

|

Dear Er.Harsoda,

There is a PPT presentation by me on the DETAILING in the forum. Also many sketches and drawings and small HB etc are available under the EXPERTS FORUM.

如果它再次启动让管理员把它作为一个年代ticky heading so that all posting containing information will be at one place. Otherwise the postings will be scattered and many may post at different heading/places. This is happening for the STAADPRO even though there is aSTICKYtopic many are posting under different heading and all the information goes as scattered ones.

T.RangaRajan. |

|

| Back to top |

|

|

B.V.Harsoda

General Sponsor

Joined: 19 Jan 2009

Posts: 2329

Location: RAJKOT,GUJARAT, INDIA

|

Posted: Sun Oct 05, 2014 5:21 pmPost subject: Posted: Sun Oct 05, 2014 5:21 pmPost subject: |

|

|

Dear Sir,

You are right that you have been already given good details but my desire is for more discussion of Detailing just like"Seismic Design "Topic. Your Suggestion for this topic as"STICKY"is also good & may be useful. I hope More response & cooperation from Admin. & all expert members of this forum.

Thanks & Regards,

B. V. Harsoda |

|

| Back to top |

|

|

B.V.Harsoda

General Sponsor

Joined: 19 Jan 2009

Posts: 2329

Location: RAJKOT,GUJARAT, INDIA

|

Posted: Sun Oct 05, 2014 5:55 pmPost subject: Posted: Sun Oct 05, 2014 5:55 pmPost subject: |

|

|

Dear Er. T. RangaRajan Sir,

Attached figure is from your PPT. My question is different, it is not covered in your figure.This is for your kind information & further your expert opinion please.

Warm Regards,

B. V. Harsoda

| Description: |

| Fig. from PPT by Er. T. Rangarajan |

|

| Filesize: |

68.53 KB |

| Viewed: |

3221 Time(s) |

|

|

|

| Back to top |

|

|

B.V.Harsoda

General Sponsor

Joined: 19 Jan 2009

Posts: 2329

Location: RAJKOT,GUJARAT, INDIA

|

Posted: Mon Oct 06, 2014 3:53 pmPost subject: Posted: Mon Oct 06, 2014 3:53 pmPost subject: |

|

|

Dear Er. T. RangaRajan Sir,

Your PPT regarding Reinforcing detailing of R.C.C members and PPT byATLANTA HOUSING LTD, House - 34, Road - 46, Gulshan-2,

Dhaka, Bangladesh, both are same.Nos of slides are also same i. e. 47 Nos. Only Name of Auther in front slide is different.Screen Shot of both are given for your kind information.

Warm Regards,

Er. B. V. Harsoda

| Description: |

| Detail of R. C. C. Members |

|

| Filesize: |

162.93 KB |

| Viewed: |

3345 Time(s) |

|

| Description: |

|

| Filesize: |

80.56 KB |

| Viewed: |

3207 Time(s) |

|

|

|

| Back to top |

|

|

thirumalaichettiar

Silver Sponsor

Joined: 26 Jan 2003

Posts: 3552

|

Posted: Mon Oct 06, 2014 4:51 pmPost subject: Posted: Mon Oct 06, 2014 4:51 pmPost subject: |

|

|

Dear Er.Harsoda,

Yes!

I know that some one from Bangaladesh has stolen this PPT and removed my name. I sent a mail but did not get answer. You can find this PPT and other documents like pile cap, tips etc that are in my name,are populated in may web sites by removing my name.

Let some body use and get its benefit.

T.RangaRajan. |

|

| Back to top |

|

|

B.V.Harsoda

General Sponsor

Joined: 19 Jan 2009

Posts: 2329

Location: RAJKOT,GUJARAT, INDIA

|

Posted: Sat Oct 11, 2014 11:29 pmPost subject: Posted: Sat Oct 11, 2014 11:29 pmPost subject: |

|

|

| 548 members have seen , but no response, except Er. T. RangaRajan Sir. I can not under stand Reason for it. |

|

| Back to top |

|

|

spsvasan

...

Joined: 18 Dec 2008

Posts: 374

|

Posted: Sun Oct 12, 2014 2:36 amPost subject: Re: Need of Detailing Awareness For Safe Structures Posted: Sun Oct 12, 2014 2:36 amPost subject: Re: Need of Detailing Awareness For Safe Structures |

|

|

Dear Er.Harsoda

Figure 1 is correct since the bending moment in the longer direction is higher and the long bars are to be kept in the lower layer. In my early days, once or twice, I had noted errors as in Fig 2 in my sites. Since then I have added a "remarks" column in my footing schedule stating "long bars are in lower layer" or "NS bars are in lower layer" etc.

Once I came across a raft beam drawing detailed similar to the floor beams - with midspan reinforcement at the bottom and support reinforcement at top. The drawing was revised before execution.

Again, in my early days, there were a few instances of failure of relatively large sunshades. Each investigation revealed that the bars of the sunshades were kept at the bottom. Each of the site was supervised by a technically qualified engineer. But the bar benders had convinced the relatively inexperienced site engineers that the bars should be at bottom so as to "hold" the concrete in place. Since then I am showing a blown up section of the sunshades with the bars clearly shown at top. I also indicate in bold letters that "bars are to be provided at top" wherever necessary.

In one case a long sunshade collapsed. The building was of load-bearing masonry and the sunshade had been de-shuttered without construction of brick wall above.

In my early days, I once designed a 1.5m sunshade present on all four sides of a courtyard. The sunshade developed diagonal cracks at the bottom at each of the four corners. At the corners, the sunshade slab had spanned between the adjacent walls. There was no bottom reinforcement and slab had cracked. Fortunately since equilibrium conditions were satisfied, the sunshade did not collapse. I created a joint at the four corners and the sunshades are behaving well. A few years later I came across the German code on RCC and this code deals specifically with this case and indicates calculation for the bottom reinforcement in such cases.

I do hope, other SEFIans will come out with their experience and observations to make this topic useful to all.

Regards

S.P.Srinivasan

| B.V.Harsoda wrote: |

Dear All,

I want to raise the Topic"Need of Detailing Awareness For Safe Structures", as I feel, it is very very important. Computer software is commonly used to provide design information, but without proper detailing & site awareness regarding detailing, design Strength can not be achieved.

Below given case I have read from Book:-

Failures in Concrete structures

By

Robin Whittle

Case of Failure of two way slab due to lake of awareness of Site Engineer toward Detailing:-

"A two-way spanning slab was designed in accordance with the design rules.One side was significantly longer than the other and this meant that the reinforcement provided for the short span was considerably greater than that for the long span.When the drawing arrived on site, the site engineer decided that the drawing contained a mistake and that the reinforcement in the long span should be the greater. He instructed the reinforcement layout to be swapped around and the slab was built that way. Later, when the full load was applied, the slab collapsed."

All of us has Design Footings, but how many has deeply observed reinforcement placing at site is the question ?

Please Refer below two Figures & say which method of reinforcement arrangement is correct and why ?

Warm Regards,

B. V. Harsoda |

|

|

| Back to top |

|

|

thirumalaichettiar

Silver Sponsor

Joined: 26 Jan 2003

Posts: 3552

|

Posted: Sun Oct 12, 2014 8:46 amPost subject: Posted: Sun Oct 12, 2014 8:46 amPost subject: |

|

|

Dear Er.Harsoda,

This is happening in this forum. Since many engineers do not pay more attention on these aspect like DETAILING etc. The same situation is for the topic of CONSTRUCTION LOADS. Do not worry and discontinue if you had reason . Most of them want free downloads, the solution for their consultancy etc as you can read the postings.

Regarding the CANTILEVER problems at site, it is good to provide 2 layers keeping the bigger size at Top layer which will help in many folds.i.e. it is good for lateral load(SEISMIC) condition and keep the deflection to certain extent. Provide min. 0.12% as for distribution bars as per code for the BOTTOM layer. This way it avoids failure of sunshades. I am doing this in my projects.

的帖子。SPS很明显,设计ners ought to provide a clear, concise drawings with notes that should be followed at site. This way it will not have any ambiguity and safe guard the designer.

Hope you will get more response from others.

With warm rehards,

T.RangaRajan |

|

| Back to top |

|

|

Sudhakaran

General Sponsor

Joined: 16 Jul 2013

Posts: 240

Location: Kannur

|

Posted: Sun Oct 12, 2014 3:06 pmPost subject: Re: Need of Detailing Awareness For Safe Structures Posted: Sun Oct 12, 2014 3:06 pmPost subject: Re: Need of Detailing Awareness For Safe Structures |

|

|

Sir,

Similar cases generally happens in the sites.

If we provided detailed drawing as per design cantilever slab they will do as drawing but some time they will provide cantilever beam at edges for supporting the slab as their on decision, while asking they tells that it is for strengthening the slab.. is it give good or bad result?

Sudhakaran.

| spsvasan wrote: |

Dear Er.Harsoda

Figure 1 is correct since the bending moment in the longer direction is higher and the long bars are to be kept in the lower layer. In my early days, once or twice, I had noted errors as in Fig 2 in my sites. Since then I have added a "remarks" column in my footing schedule stating "long bars are in lower layer" or "NS bars are in lower layer" etc.

Once I came across a raft beam drawing detailed similar to the floor beams - with midspan reinforcement at the bottom and support reinforcement at top. The drawing was revised before execution.

Again, in my early days, there were a few instances of failure of relatively large sunshades. Each investigation revealed that the bars of the sunshades were kept at the bottom. Each of the site was supervised by a technically qualified engineer. But the bar benders had convinced the relatively inexperienced site engineers that the bars should be at bottom so as to "hold" the concrete in place. Since then I am showing a blown up section of the sunshades with the bars clearly shown at top. I also indicate in bold letters that "bars are to be provided at top" wherever necessary.

In one case a long sunshade collapsed. The building was of load-bearing masonry and the sunshade had been de-shuttered without construction of brick wall above.

In my early days, I once designed a 1.5m sunshade present on all four sides of a courtyard. The sunshade developed diagonal cracks at the bottom at each of the four corners. At the corners, the sunshade slab had spanned between the adjacent walls. There was no bottom reinforcement and slab had cracked. Fortunately since equilibrium conditions were satisfied, the sunshade did not collapse. I created a joint at the four corners and the sunshades are behaving well. A few years later I came across the German code on RCC and this code deals specifically with this case and indicates calculation for the bottom reinforcement in such cases.

I do hope, other SEFIans will come out with their experience and observations to make this topic useful to all.

Regards

S.P.Srinivasan

| B.V.Harsoda wrote: |

Dear All,

I want to raise the Topic"Need of Detailing Awareness For Safe Structures", as I feel, it is very very important. Computer software is commonly used to provide design information, but without proper detailing & site awareness regarding detailing, design Strength can not be achieved.

Below given case I have read from Book:-

Failures in Concrete structures

By

Robin Whittle

Case of Failure of two way slab due to lake of awareness of Site Engineer toward Detailing:-

"A two-way spanning slab was designed in accordance with the design rules.One side was significantly longer than the other and this meant that the reinforcement provided for the short span was considerably greater than that for the long span.When the drawing arrived on site, the site engineer decided that the drawing contained a mistake and that the reinforcement in the long span should be the greater. He instructed the reinforcement layout to be swapped around and the slab was built that way. Later, when the full load was applied, the slab collapsed."

All of us has Design Footings, but how many has deeply observed reinforcement placing at site is the question ?

Please Refer below two Figures & say which method of reinforcement arrangement is correct and why ?

Warm Regards,

B. V. Harsoda |

|

|

|

| Back to top |

|

|

|

|

|

Youcannotpost new topics in this forum

Youcannotreply to topics in this forum

Youcannotedit your posts in this forum

Youcannotdelete your posts in this forum

Youcannotvote in polls in this forum

Youcannotattach files in this forum

Youcandownload files in this forum

|

|

|